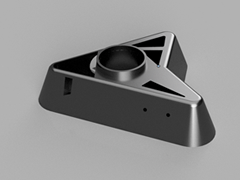

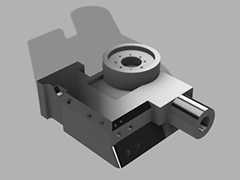

- Perfect Machining Center of being able to process with 5-axis at the same time.

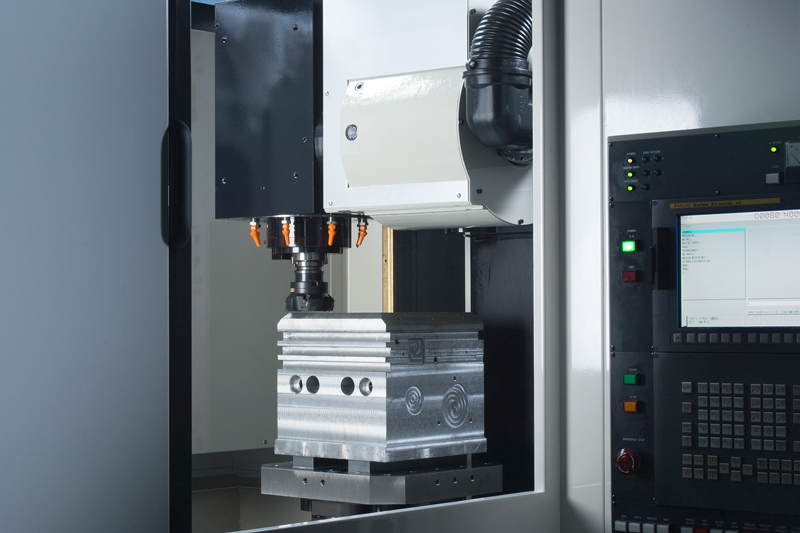

- Perfect vertical Machining Center.

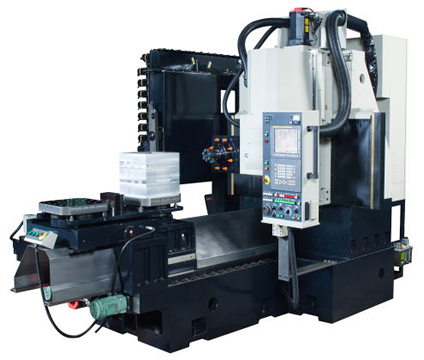

- Perfect 2-Pallet Horizontal Machining Center.

- Machining slope perfectly.

- The new model has FANUC high torgue at A and B(C) axis with high performance DD motor built-in.

- Extremely high accuracy and high performance processing can be done due to the installation of Scale Feedback and DD motor.

It is the first machining center which has various perfect functions.

©Patent right was registered in October,2015.

JKM

JKM